Rail Comfort System | the

elastic rail encapsulation

RCS (Rail Comfort System)

the problem solver for your individual rail encapsulation system

The embedding of rail in the inner-city infrastructure places high demands on planners and coordinators. Tram traffic causes enormous shocks and vibrations in the vicinity of the track, which in many cases leads to damage to the surrounding superstructure, making frequent repairs necessary.

By using SEALABLE‘s Rail Comfort System, individually adapted to your project, problems of this kind can be avoided, the track can be decoupled from the adjacent superstructure and vibrations from tram traffic can be reduced to a great extent. The discharge of stray current is reduced to a minimum by our insulations.

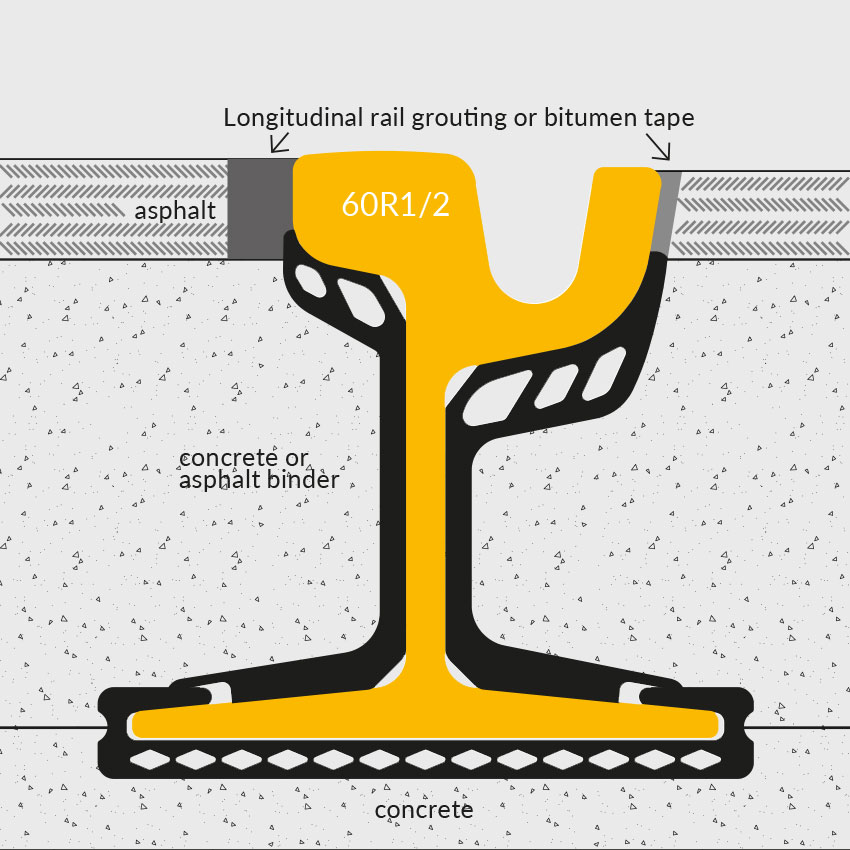

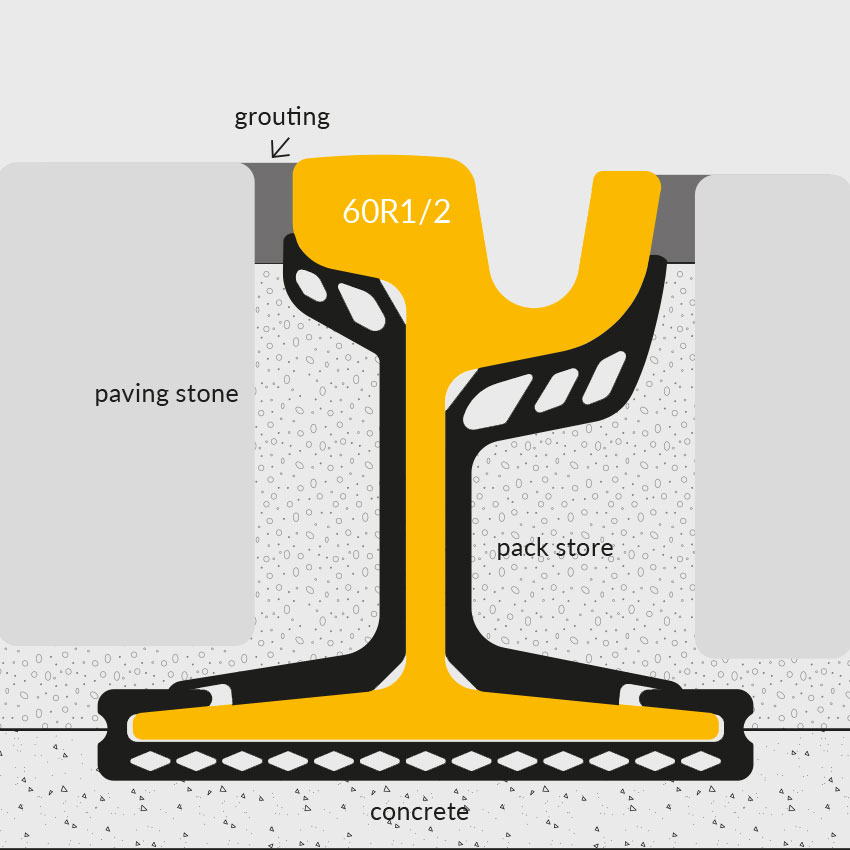

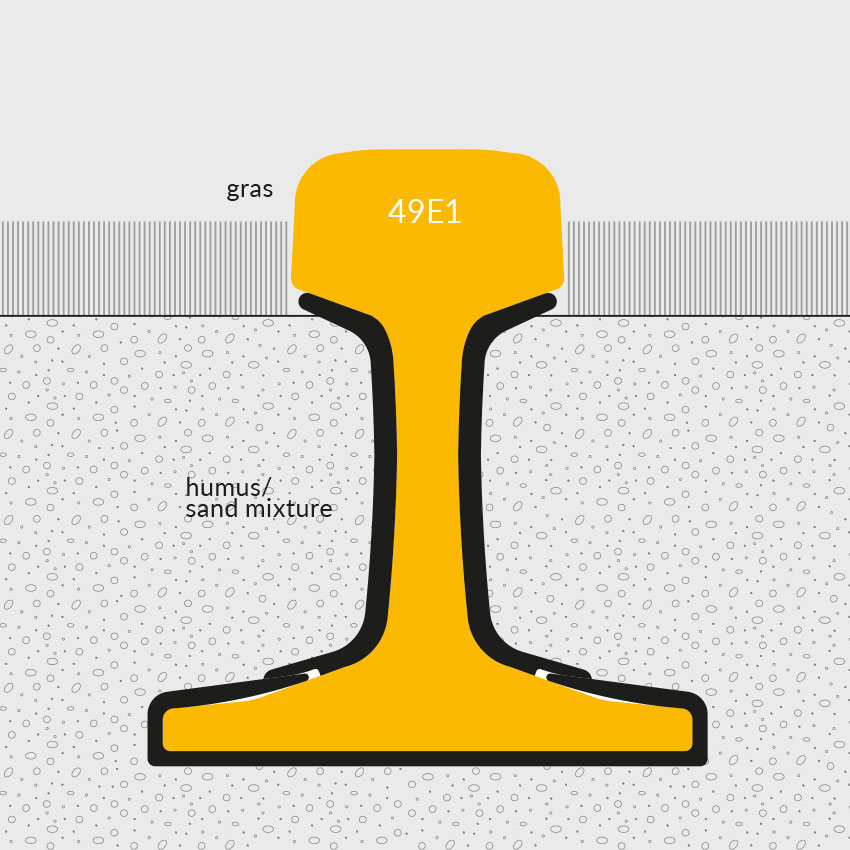

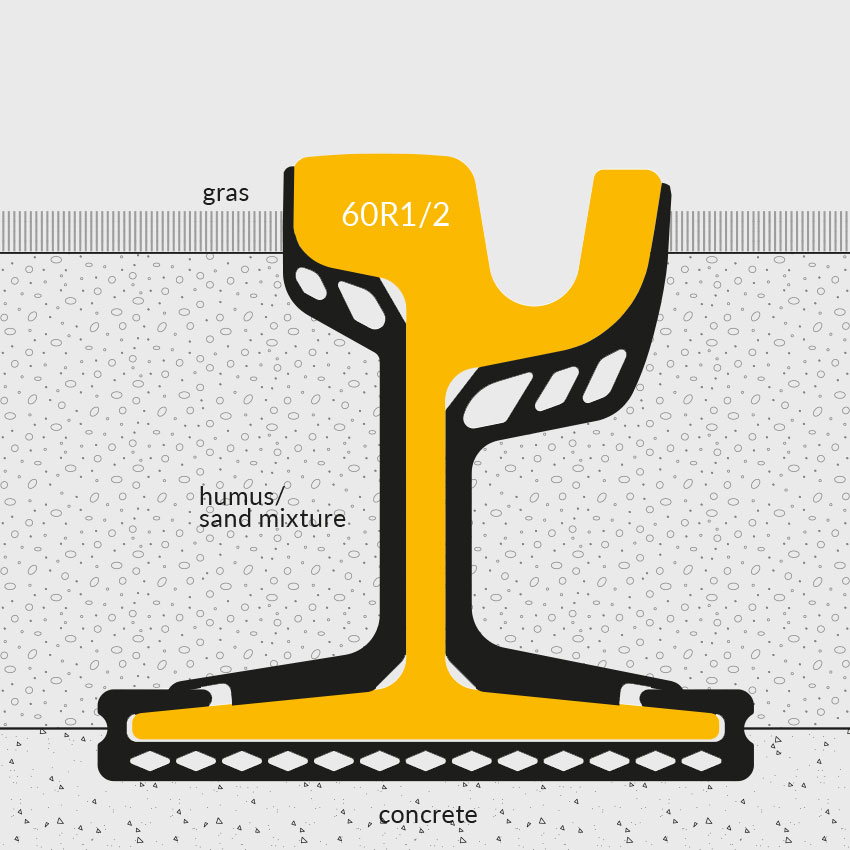

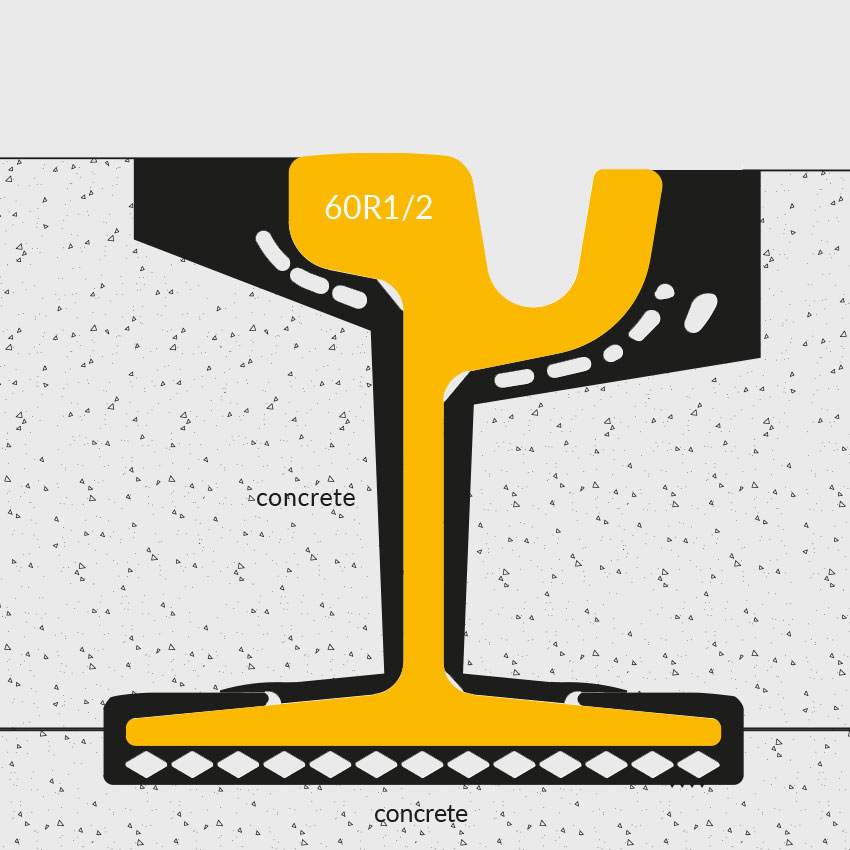

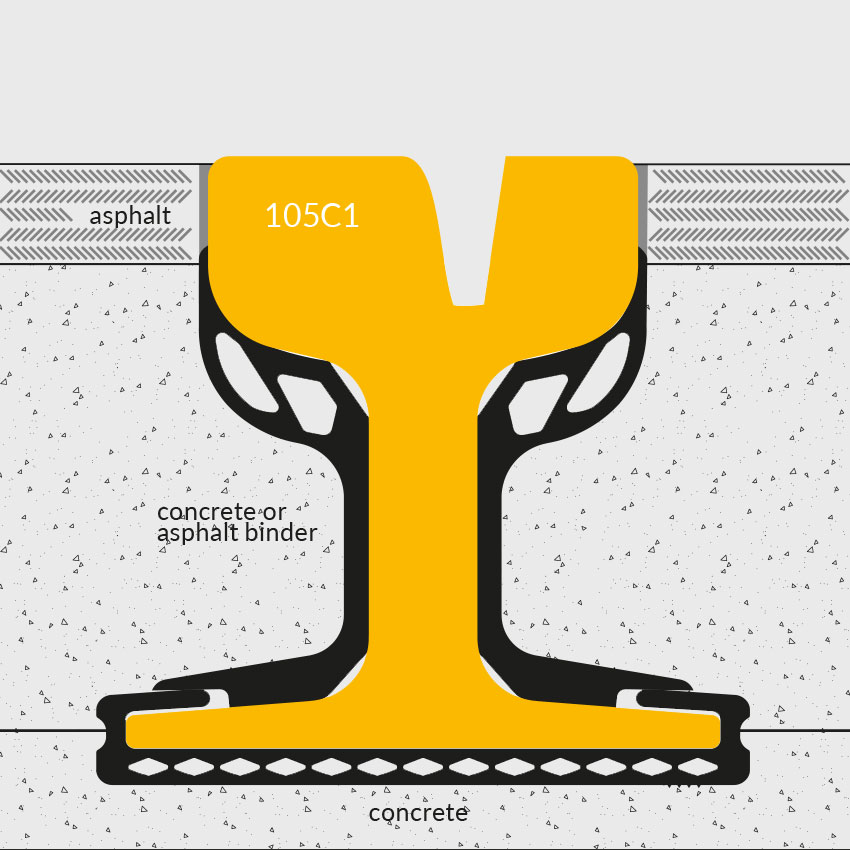

The Rail Comfort System is suitable for use in any type of covering - whether road track (asphalt, paving, concrete) or grass track. Thus, the RCS® offers visual and functional added value at the same time. Our all-in-one solution can be adapted 100% to your requirements and thus offers maximum flexibility.

With the RCS® (Rail Comfort System), surrounding buildings are protected from structure-borne noise and the quality of life of residents is improved.

Robert Wörfel, Product Manager Track Superstructure

The best protection against structure-borne noise and stray current

With urbanisation, cities are growing and with them rail-bound traffic is moving even closer to the built-up area. Vibrations can have a considerable impact on the environment and severely impair the quality of life. With sensitive installations and equipment, even the smallest

vibrations can lead to a loss of quality. We specialise in developing effective solutions to reduce vibrations. In addition, metallic structures such as pipelines, tank vessels, reinforced cable sheaths and reinforced concrete structures are exposed to a corrosion risk due to the influence of unwanted stray currents.

SEALABLE offers you effective elastic rail support systems that not only reduce stray current losses but also make a significant contribution to avoiding structure-borne noise in daily railway operations.

STRAY CURRENT INSULATION

RCS® meets all your requirements for complete and sustainable rail insulation. It is perfectly suited for any type of rail profile, as well as switches and crossings.

REDUCTION OF STRUCTURE-BORNE NOISE

By reducing structure-borne noise with our Rail Comfort system, surrounding buildings are protected and the quality of life for residents is improved.

Areas of application

Heat resistance

In the course of regular maintenance work on rails in tracks, switches and crossing systems, it is common practice to regularly weld on the rails, especially in the case of grooved rail tracks with a cover. This so-called build-up welding on rails makes it possible to extend the service life of the rails and thus delays cost-intensive rail replacements in the roadflush track system. It is important that the insulation of the rails is resistant against such work, otherwise maintenance becomes a costly affair.

We can guarantee the heat resistance of our insulation for wear-related overlay welding work or also the reprofiling of tthe rails. This property of the Rail Comfort System, as well as its resistance to hot bitumen, has been proven by tests carried out by independent institutes.

Thanks to its special compound properties, the material is heat-resistant and can withstand temperatures above 270°C for a short time.

Alexander Moog, Application Engineer Track Superstructure

Easy handling with our Rail Comfort System

In addition to stray current insulation and structure-borne noise insulation, another important factor for the selection of an optimal rail encapsulation system is the easy handling.

In contrast to many other systems, the RCS® can be pre-assembled both locally and temporally independent of the construction progress. This means that the insulation is not tied to weather conditions or construction and closure times. Delivery is possible just-in-time, which avoids logistical bottlenecks.

In addition, this approach guarantees the highest level of quality and safety during installation. Contamination and improper assembly due to lack of time or untrained personnel do not occur with this option. The pre-assembly of the track components, for example, takes place in the factory under optimal temperature and working conditions.

Our services

CALCULATIONS

TESTS

LABORATORY

ONE-SITE-SERVICE

Your contact person

Language: ENG / GER

Language: ENG / GER