Tunnelling | Sealing solutions

for machine tunnel construction

concrete segment gaskets

In tunnel construction, construction projects are subject to a very high degree of complexity. Heterogeneous soil conditions, different rock types or high-water pressure are circumstances that place high demands on the material used and the machines to be used. To always meet customer needs and to be able to offer the best possible sealing solutions, we constantly advance the further development of our products and thus regularly set standards for new developments.

Types of segment seals at a glance

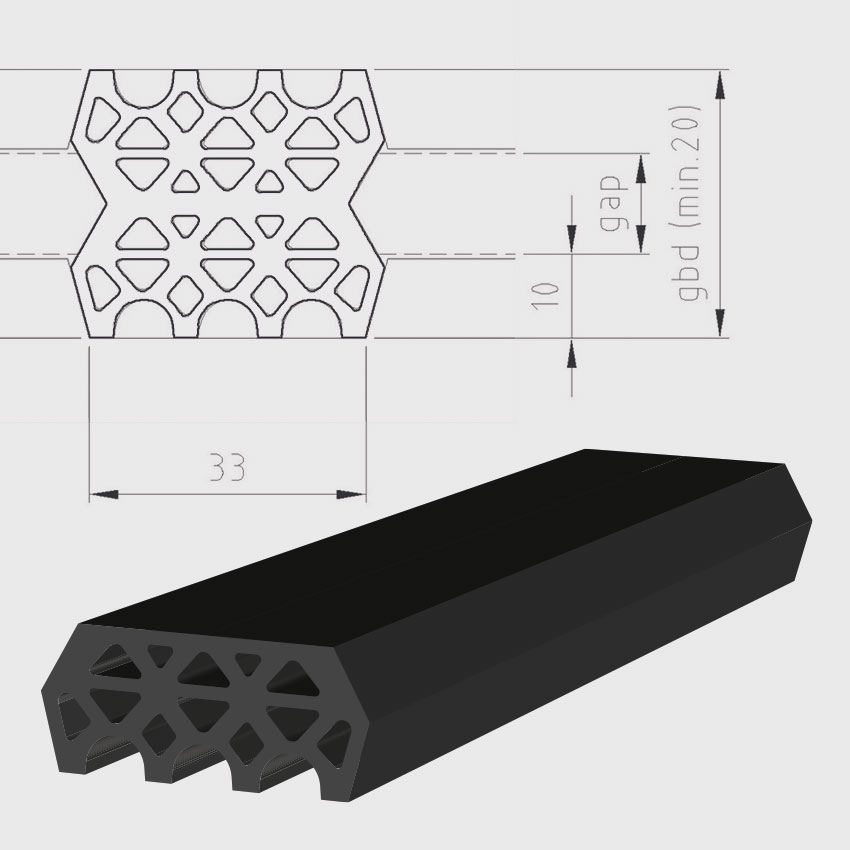

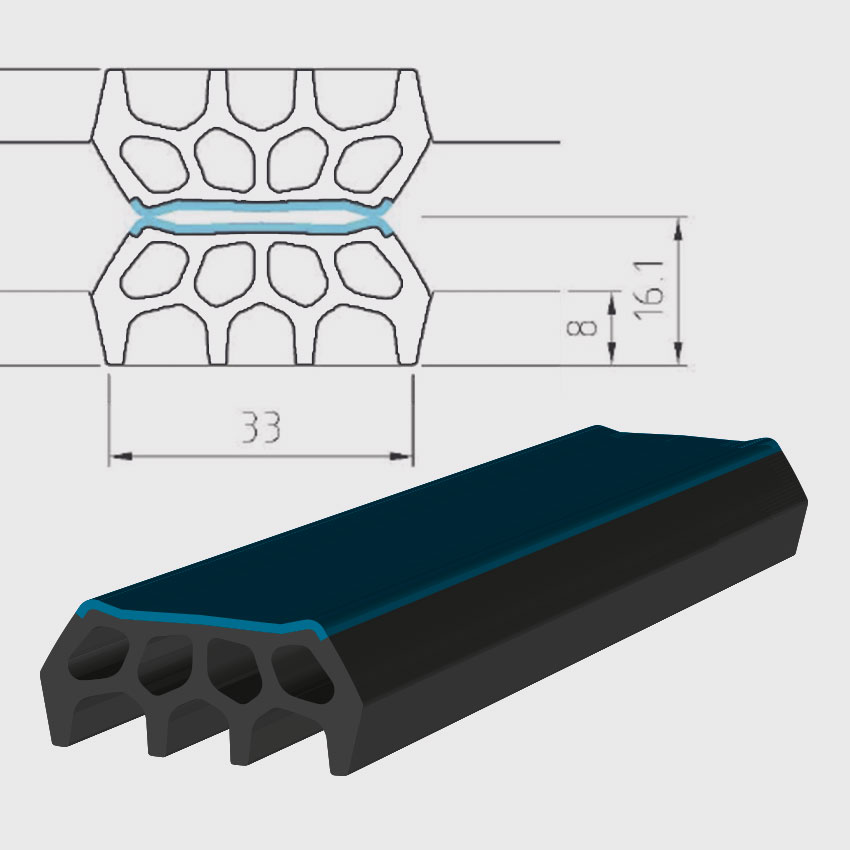

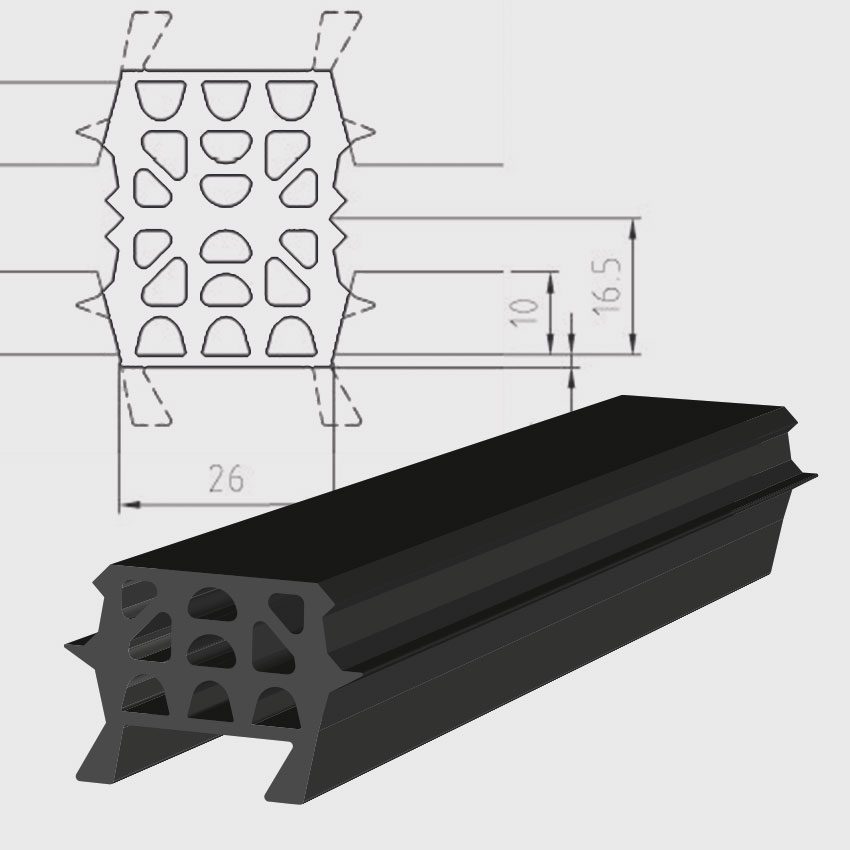

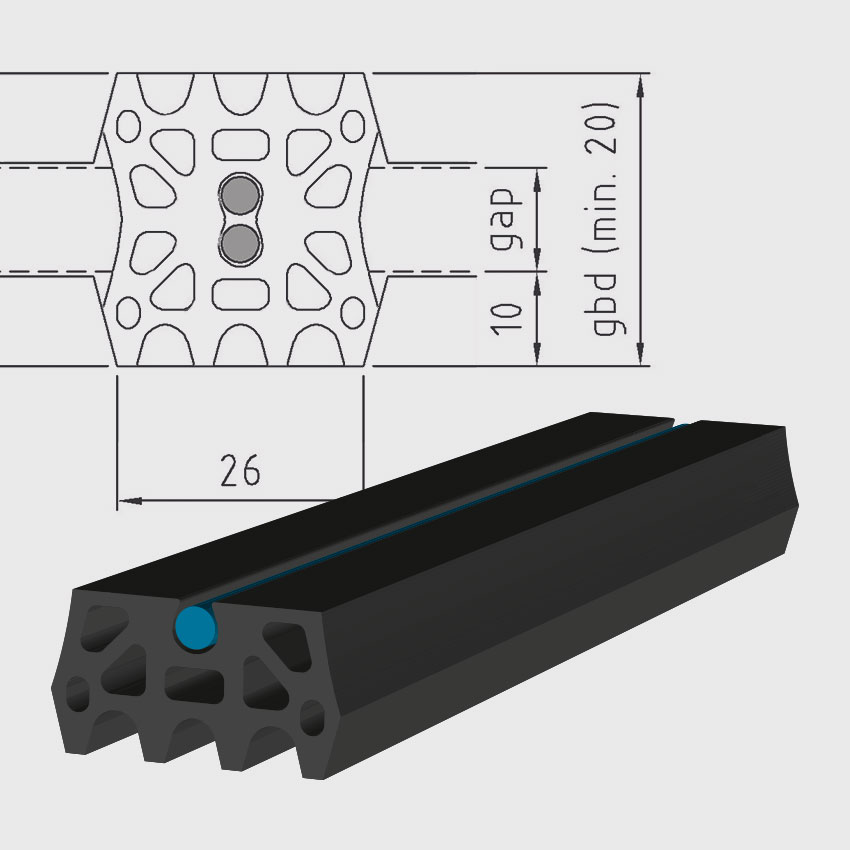

It all started with the glued-in gaskets more than 50 years ago. This was followed by anchored or cast-in sealing profiles developed by our company in 1990. In addition to the classic mono compression seals, there are now also various combinations with hydrophilic swelling materials or fiber anchored gaskets for even more effective performance of our products.

Fiber anchored tunnel gaskets

Customer requirements for sealing in mechanised tunnelling have increased enormously in recent years, both in terms of material and compounds as well as the degree of individualisation and cost input. In this way, we strive to take customer wishes into account and incorporate them into the development of our products.

The fiber-anchored sealing profiles are the latest development in the field of tunnel sealing. The many small fibres at the bottom of the profile result in a significantly better fastening in the concrete segment.

"SEALABLE tunnel gaskets have a high degree of flexibility in geometry: the material properties meet the highest requirements in terms of long-term relaxation, which ensures the tightness of a construction throughout its entire service life."

Andreas Artus, Head of Process Engineering

Performance Corner

Without a perfectly fitting corner, even the best seal is only half as good. Each segment in the segment ring has its own individual corner angle and, above all, the K-brick must be integrated at the end for a perfect fit. Our profiles are joined by a special process, injection moulding, to form a finished, closed sealing frame. The connecting link is the so-called "Performance Corner", which not only has a variable corner length and different degrees of hardness, but also the opening angle as well as the twisting angle can be individually adjusted.