Trackbed Mats | Structure-borne noise insulation for rail traffic

Trackbed Mats

comfortable trains need a comfortable track bed

SEALABLE‘s high-quality ballast mats for mainline, suburban, underground and urban railway lines effectively reduce operational vibrations and structure-borne noise emissions. For more than 50 years, these products have proven themselves in practical use without any complaints.

An experienced team of specialists from various fields developed the comprehensive system technology. Trackbed mats from SEALABLE therefore not only meet all the requirements of modern track systems, but can also be adapted to individual requirements and conditions. A coordinated range of accessories enables cost-effective installation.

Already during the planning of a new railway line, the future urban development along the tracks must be considered, because:

„You made your bed, now sleep in it...“.

Robert Wörfel, Produktmanager Track Superstructure

The best protection against vibrations

and structure-borne noise emissions

Vibrations can have a significant impact on the environment and greatly impact the quality of life. For sensitive installations and equipment, even the smallest vibrations can lead to a loss of quality. We specialise in developing effective solutions for vibration reduction.

Our ballast mats increase the stability of track layers and thus reduce ballast pressure. With sub ballast mats it is possible to introduce a lot of elasticity into the superstructure. This makes it possible to defuse critical transfer points between nballast and bridge supporting structure or tunnel floor. Even on heavily used tracks, this reduces the maintenance effort to a minimum.

SEALABLE offers elastic trackbed mats which, due to high-quality materials, make a significant contribution to the mitigration of structure-borne noise in daily railway operations. They retain their function in the long term, regardless of environmental influences such as frost or heavy soiling of the ballast bed.

Test methods

FEM SIMULATION

With the help of FEM simulation, our products are constantly being further developed and optimised. This expertise enables a holistic approach that takes into account a wide range of influencing variables.

SPRING CURVE

The static and dynamic spring curves are important parameters for determining the appropriate rail insulation. Depending on the area of application, a different mat geometry with suitable bedding module is used.

Independent test institutes have examined the SEALABLE trackbed mats for their suitability. All types have been approved in accordance with DBS 918071 (formerly TL 918071) of DB AG for a wide range of applications - including high-speed lines.

Certification as a Q1 supplier of DB AG with regard to performance, production and qualityrelated parameters has also been obtained.

SEALABLE ballast mats are functional and durable capital goods that have gained worldwide acceptance. This internationally established image can be proven by the references for both the new construction and renovation of rail transport routes.

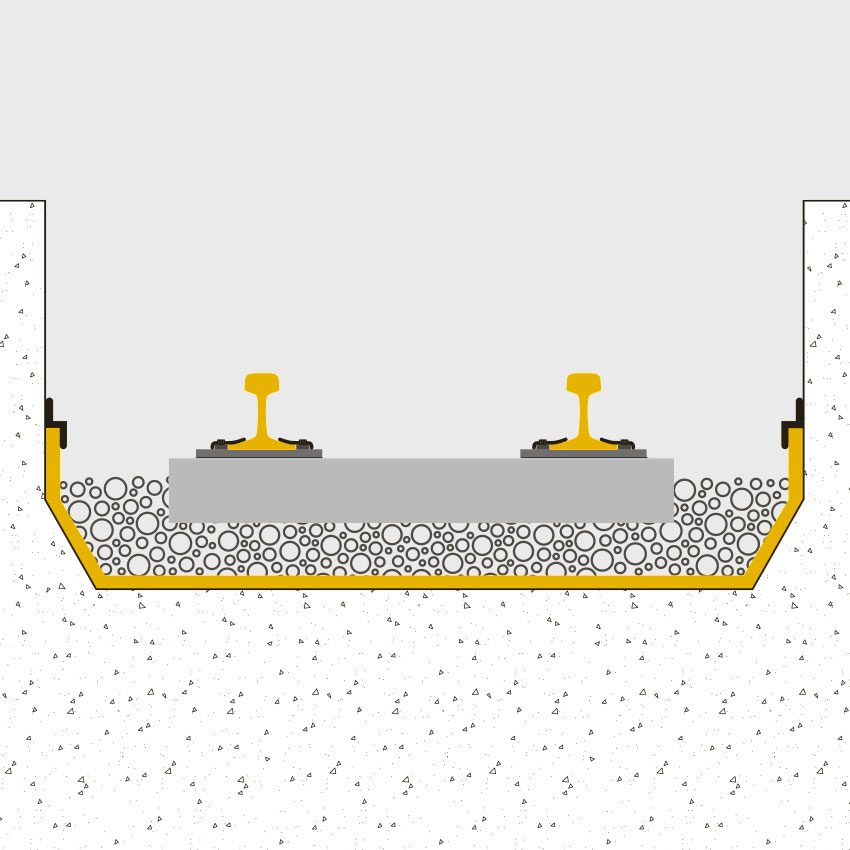

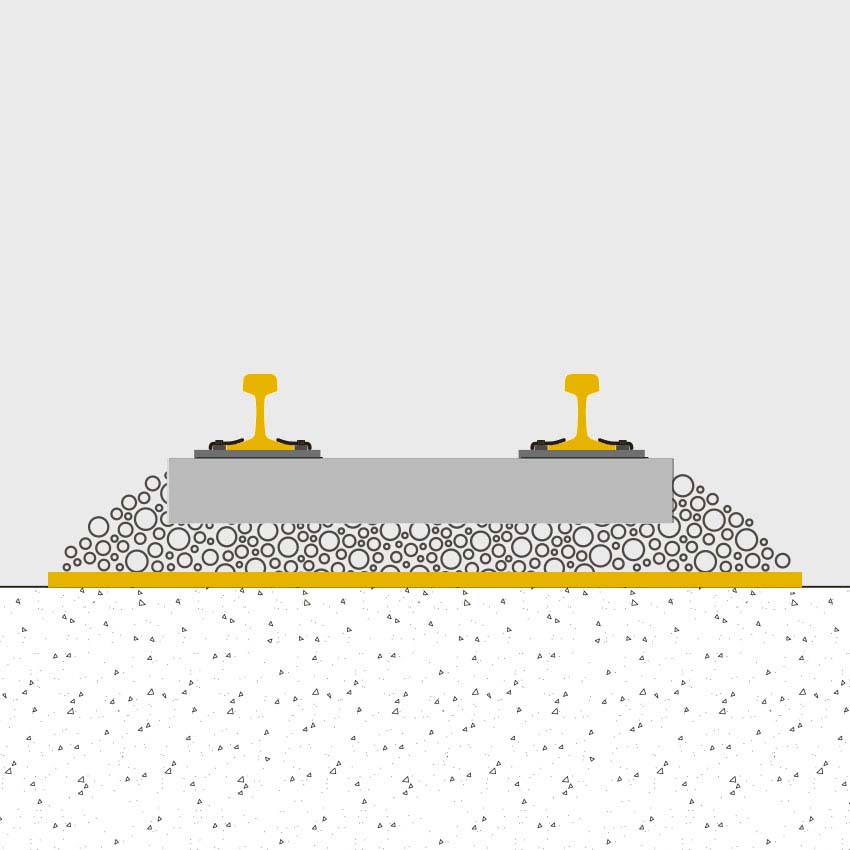

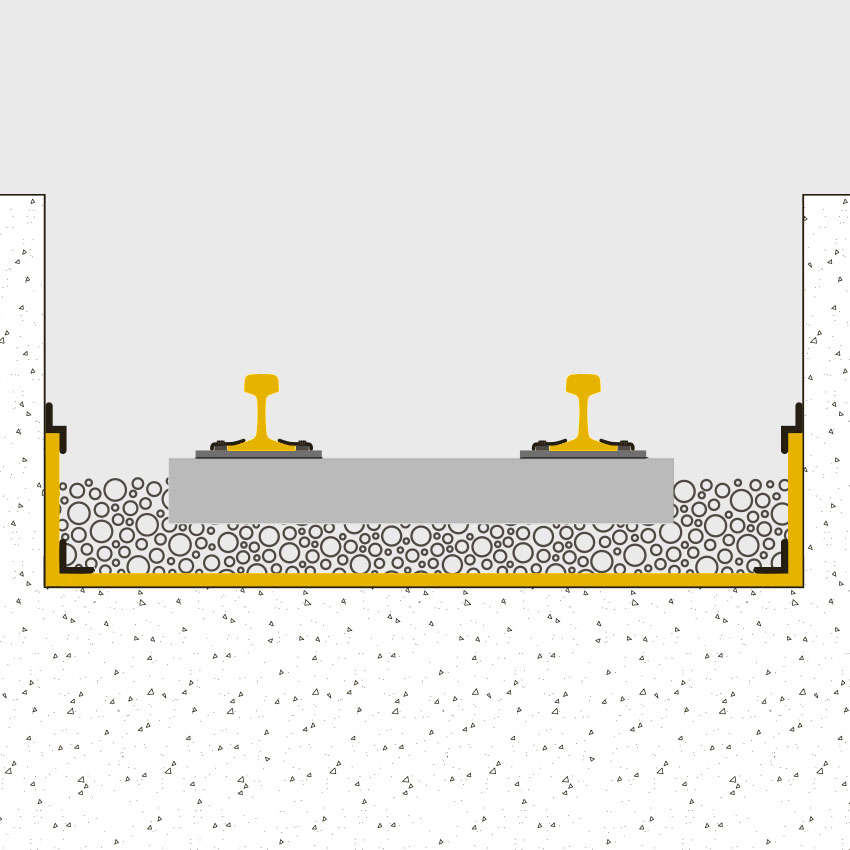

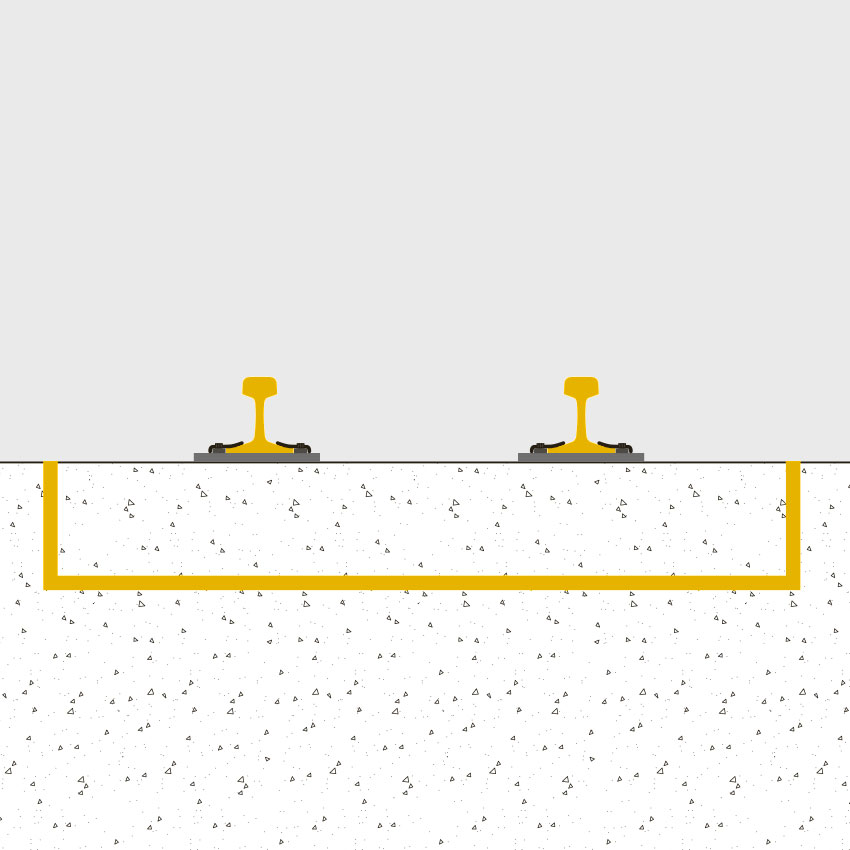

Areas of application

Easy handling with our trackbed mats

The installation of SEALABLE trackbed mats is characterised by functionality and easy handling. The rolls of mats, which are marked accordingly at the factory, are distributed and laid out at the destination according to the installation plan. Alternatively, the mats can be cut to size individully on site.

The special „Click & Connect“ system ensures ease of work and time savings. And: SEALABLE ballast mats do not necessarily have to be glued to the surface. The only prerequisite for easy installation is a well compacted ground surface.

Another advantage is that the installation of the base mats and the use of side mats can be individually adapted to local conditions. Drainage devices can also be operated without any problems.

Our services

CALCULATIONS

TESTS

LABORATORY

ONE-SITE-SERVICE

Your contact person

Language: ENG / GER

Language: ENG / GER