RailRestore | First aid for broken rails

repair the broken rail quickly and easily with

SEALABLE RailRestore

A broken rail is not uncommon in ongoing railway operations and poses several dangers. The breakage point necessitates slow passage, as it can lead to a train derailment in the worst-case scenario. Delays as well as personal injury or property damage may result. To avoid damage and accidents, railway companies regularly monitor their tracks by using special maintenance and monitoring technologies. This allows to detect and repair broken rails in early stages.

But what happens when a defective rail is discovered?

The track must be closed and the rail section repaired. In order to maintain rail traffic and ensure the safety of everyone involved, it is important that broken rails are repaired quickly and safely. In order to restore the situation promptly, we have developed a rail joint bar that allows you to repair the rail quickly and easily. With SEALABLE RailRestore, broken rails are eliminated in the shortest possible time and at the highest level. A complex rail replacement is avoided and the associated long-term track closure is prevented.

RailRestore is available for various rail types. Common types such as Ri60, 105C1, or S49 are available directly from stock. If required, we will be happy to produce a RAILRESTORE for your specific rail and support you in selecting and installing the best solution for your infrastructure.

Why our RailRestore?

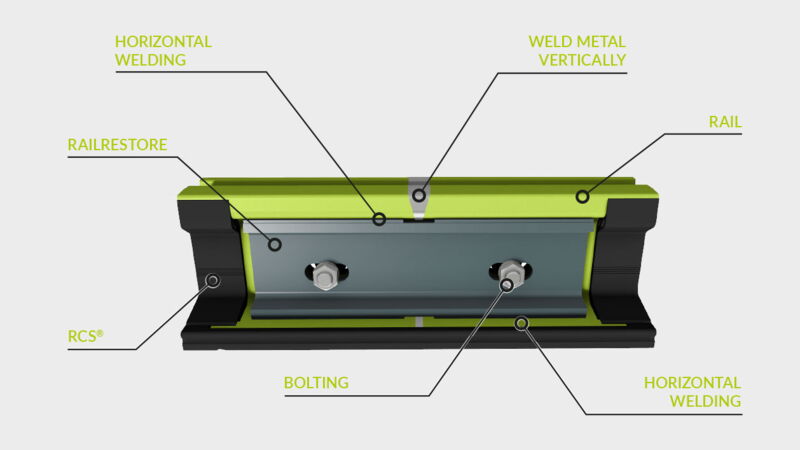

The SEALABLE RAILRESTORE is a patented solution for broken rails that eliminates the need for complex repair work. It consists of a joint bar that is easily and quickly mounted around the broken rail. Only the section (approx 0.5 m) around the damaged area must be exposed. The RAILRESTORE components are fixed to the rail via two holes and bolts. By bolting RAILRESTORE to the rail, it is vertically stabilized and aligned in horizontal and vertical directions at the same time. This allows trams to run over the tracks again shortly after installation. Additional repair work, such as welding and insulating the repaired area can be done in parallel.

Prevention of new rail fractures

Typically, the high heat that is generated during the welding process, destabilizes the metal inside the rail around the damaged area. This increases the risk of a new fracture nearby. The RAILRESTORE is firmly connected to the rail and reinforces the repaired area and preventing any further fracture in the area before and after the weld.

- Time saving of 20 % to 30 % compared to conventional methods

- The rail operation can continue even during the repair

- Bolting connection stabilizes the rail vertically at the break and aligns it both horizontally and vertically

- Welding and fastening of the RAILRESTORE prevents further breaks

- Weld pool backing

- Reducing long-term costs

In order to maintain rail traffic and ensure the safety of everyone involved, broken rails must be repaired quickly. SEALABLE RailRestore is the ideal solution for broken rail. It enables fast, safe and long-lasting repairs while reducing long-term costs.

Alexander Rüdt, Basler Verkehrsbetriebe

RCS® for RailRestore Insulation

The Rail Comfort System decouples the track from the adjacent superstructure and significantly reduces shocks and vibrations caused by tram traffic. The highly effective mounting also serves as stray current insulation and vibration damping. It is an affordable, environmentally friendly full insulation for grooved rails with the aim of minimizing stray current and reducing structure-borne noise. RCS® can be used in all known superstructure constructions. The 3-part profile system is individually adaptable to different rail types. The customized profile geometries enable cost-effective and easy installation.

If a broken rail occurs on a track insulated with RCS®, this area can be re-insulated as well. For this purpose, a special two-piece cuff was developed to cover the RailRestore. The base covering remains intact, and only the side profiles are supplemented with the new cuff. It is bonded and sealed similarly to the RCS®.

Unsere Serviceleistungen

BERECHNUNGEN

PRÜFUNGEN

TECHNIKUM

VOR-ORT-SERVICE

Ihre Ansprechpartner

Language: ENG / GER

Language: ENG / GER