Safety Profiles | one less

source of danger

Rail meets road

Safery profiles for accident reduction

Long employee outage times, increasing insurance expenses – all these factors are consequences of a rather small gap. The safety profile “Rail meets road” from SEALABLE provides a toolbox on long-lasting and reliable profiles to solve these problems quickly and efficiently.

SEALABLE safety profiles help to ensure that embedding the rail in the road no longer places great demands on planners and designers.

The ICE plant in Cologne Nippes has a capacity of 4 tracks á 410 meters where up to 8 units of the ICE 1,2,3 and up to four units of the

ICE 4 can be maintained. Employees of the plant are using bikes and scooters to et around. To support the staff, driverless vehicles are

used. To ensure a barrier-free workspace between Human and Robot, 260 meters of track were equipped with safety profiles from SEALABLE.

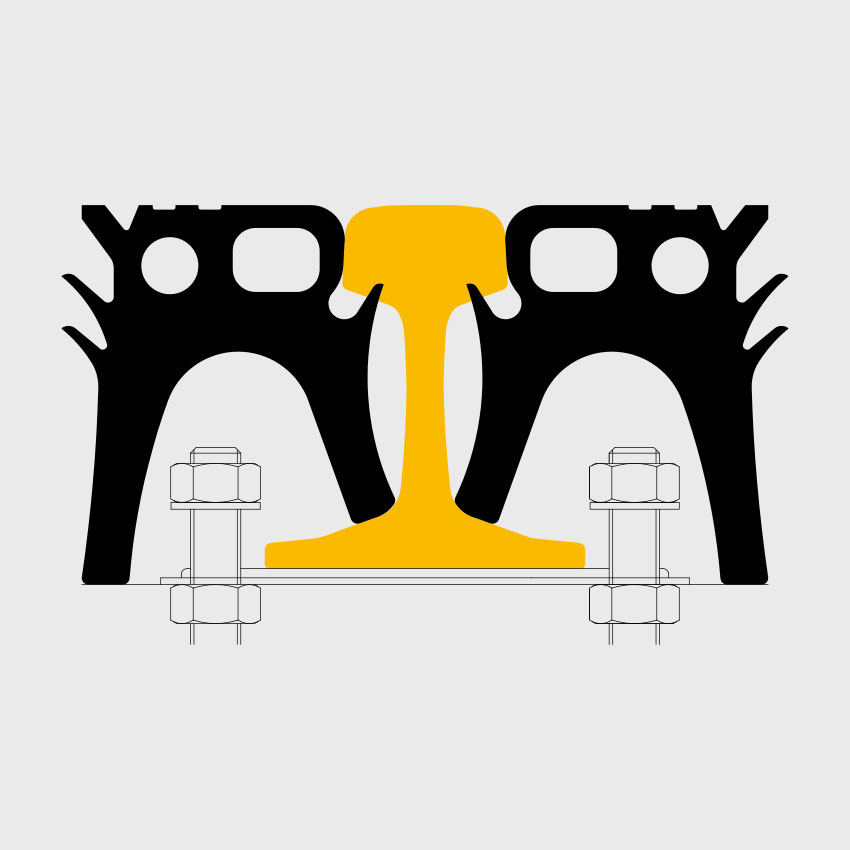

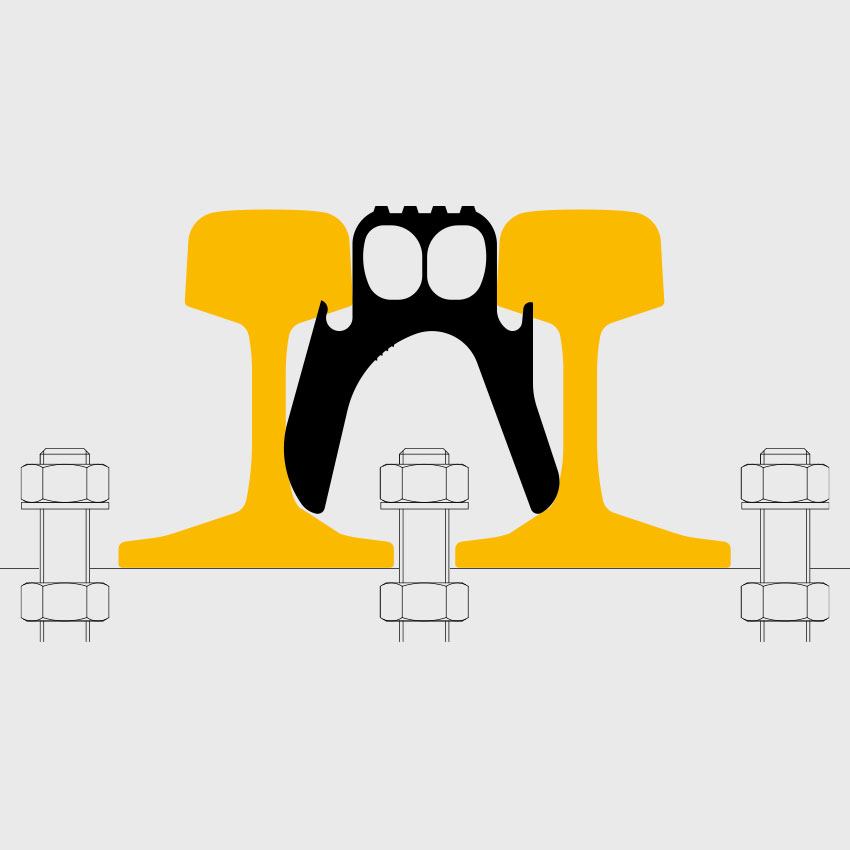

The crossing of track and road

The mostly problematic connection of the rail to the road connection due to high-maintenance grooves and the risk of accidents for pedestrians and cyclists due to open grooves should be emphasised.

In many cases, the connection of the rail to the floor covering in the area of the grooves is only unsatisfactory, especially in manufacturing plants and workshops. The space required for the wheel of the rail vehicle often constitutes a major accident hazard. This problem also applies to level crossings or factory roads.

By using a permanently elastic material from SEALABLE, geometrically matched to the respective installation location, problems of this kind can be solved, accidents avoided and the availability of the track decisively extended.

Construction types

Lifetime & maintenace

These products are wearing parts and are used under different conditions. This is the reason why it is not possible to make an estimation of the product lifespan. Unfortunately, this is also the reason why we can not make warranties concerning the durability of our profiles.

There are multiple ways to expand the lifetime of the product:

- Avoid Contamination in the area of the grooved hose

- Do not drive foreign objects into the profile

- Avoid jerky braking or acceleration movements in the longitudinal direction of the tread

- Avoid turning or steering movements of a wheel on the profile

The material used for our products aligns with the current norm concerning EPDM: DIN 7865 - Elastomeric-Water stops for sealing points in concrete. Through its excellent ageing resistance, its reduction of airborne-sound radiation of tracks and its resistance against permanent deformation, the synthetic rubber suits as perfect material for the track industry. Furthermore, EPDM is resistant to extreme temperatures, insensitive to oxidation, resistant to various chemical products and holds dielectric properties.

Our services

CALCULATIONS

TESTS

LABORATORY

ONE-SITE-SERVICE

Your contact person

Language: ENG / GER

Language: ENG / GER