New groove geometry | patented

by SEALABLE

New prevention against concrete spalling on tubbings

It is generally known that the design of segments tends to become thinner and thinner due to cost, handling and environmental aspects. As a result the contact area between the segment has to be increased as much as possible, which will lead in turn reducing the distance for the gasket to the edge of the segment. Consequently, this means that the space available for the gasket is becoming smaller. The gasket is pushed further and further to the outside edge of the segments. If sufficient and necessary concrete cover is not possible with the gasket very close to the edge, spalling of the concrete can occur during gasket compression, prompting water to find its way below the gasket and ultimately causing leakage.

What is new about our patented profile?

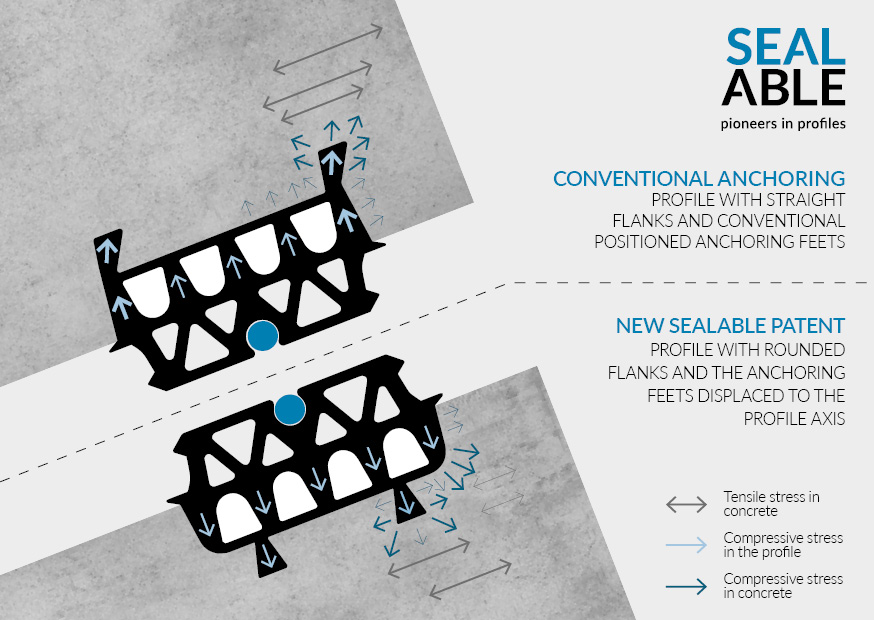

Since spalling occurs largely as an extension of the anchoring foot position, it was important to shift this force and redirect it further from the outer edge into the concrete via the inwardly placed feet away from the edge of the gasket.

In order to achieve an even better distribution, we redesigned the gasket shape as well on the flank. It is no longer straight, no longer angular, but: rounded!

The tensile and compressive stresses in the concrete are shifted inwards, through the combination of embedded anchoring feet and rounded flanks, away from the outer edge of the segment.

This solution offers the advantage that the gasket can be replaced more easily if damaged. On the one hand, the cutting process is simplified for smaller groove bases by simultaneously removing the anchoring feet, and on the other hand, possible breakouts in the concrete that occasionally occur during replacement can be covered completely and offer no direct lateral attack for leakage under the gasket.

Our Research & Development Manager for Tunnelling Oliver Pasemann says with conviction:

Being proactive and respond appropriately to these requirements, SEALABLE is making an innovative and valuable contribution with our new patent.

The patent is applied to anchored profiles with a groove base width of ≥ 33 mm. The first reference project is the Swinemünde Road Tunnel, where the M80382 profile (44 mm groove width) is used.

Sometimes you have to rethink in order to develop something innovative.

Matthias Klug, Managing Partner

Our mission is to create high-quality products that ensure a lifetime of tightness. We continue to work on our products until they are perfectly adapted to the needs of our customers. This is how this patented profile came into being. We have to move with the times and not look back.